So, What Are Metal Fabrication Techniques? Metal fabrication techniques can be broken down into two main categories: welding and machining. Welding is the process of joining metal pieces together by heating them until they reach a molten state and then using a special welder to form the joint. Machining is the use of tools to cut or shape metal parts. American Sheet Metal provides the solution to many manufacturing problems. There are many different machining techniques, but all of them rely on one or more of three basic principles: cutting, shearing, or crushing.

In the metal processing stage, materials are crushed, roasted, and then separated using magnetic or other physical forces. Next, the various elements are extracted from the metal through various methods such as flotation and leaching. The five stages of metal processing are crushing, roasting, magnetic separation, flotation, and leaching. Each stage has its own unique set of requirements that must be met to produce a quality product.

Crusher: In the crushing stage, materials are reduced in size by force. This is often done using large stones or a crusher plant. The goal is to reduce the size of the material to a suitable level for further processing.

Roaster: In the roasting stage, metals become heated until they reach their peak temperature. This process causes some of the elemental atoms in the metal to break down into smaller pieces.

Magnetic separation: It is the step in metal processing and it separates the various metals based on their magnetic properties.

Flotation: It separates the different metals based on their density and allows for easier extraction of the desired metal.

Leaching: It removes impurities from the metal by transferring them to a liquid medium.

The number of industries that require metal fabrication is growing. This is because metals are versatile and strong materials that can be used in a variety of ways. By knowing What Are Metal Fabrication Techniques, you may want to know why metal fabrication is needed. Some of the most common reasons why metal fabrication is needed are as follows:

Metal fabrication can be used to create objects that are both practical and beautiful. For example, metal frames for glasses or jewelry can be very stylish and durable. Architectural Metal fabrication can also be used to create objects that are necessary for everyday life.

For example, metal plates and bowls can be used to prepare food or drink, and metal pipes can be used to convey water or gas. Metal fabrication can also be used to create objects that are necessary for safety purposes. For example, metal railings and gates can protect people from dangerous surroundings.

Sheet metal fabrication is a process that produces a variety of products from sheet metal. The benefits of sheet metal fabrication include high-quality products, faster production times, and reduced manufacturing costs. Sheet metal fabrication can produce products that are used in a variety of industries, including transportation, aerospace, and medical devices. The benefits of sheet metal fabrication include:

High-quality products: Sheet metal fabrications produce high-quality products due to the multiple steps involved in the process. Multiple operations are performed on the raw material to create the finished product. This includes cutting, shaping, welding, and annealing.

Faster production times: Sheet metal fabrications can produce products quickly due to the automated processes used in the manufacturing process. This reduces lead time and improves overall efficiency for businesses.

Reduced manufacturing costs: Reduced manufacturing costs are key, as is the ability to create unique products with little to no competition. Additionally, sheet metal fabrication offers a high degree of precision and accuracy, which can be important in certain industries.

So, What Are Metal Fabrication Techniques, and who needs metal fabrication? Several industries and businesses rely on metal fabrication. This process involves cutting, shaping, and assembling metals into various structures and components. Fabrication is often used to create products such as machinery, buildings, and vehicles.

Many businesses in the construction, engineering, and manufacturing sectors need metal fabrication services. For example, fabricators may be required to create structural steel beams for use in the construction of bridges and skyscrapers. They may also be needed to produce parts for machinery or vehicles.

Metal fabrication is a highly skilled trade that requires a lot of experience and training. Many fabricators are employed by specialist companies that provide their services to other businesses. Some fabricators may also work directly for manufacturers or construction firms.

Metal fabricators are in high demand as the global economy rebounds. There are many factors to consider when selecting a metal fabricator, but some of the most important factors include experience, quality control, and delivery time.

Experience is key for any metal fabricator. A company that has been in business for several years is more likely to have the knowledge and skills needed to deliver a quality product on time. Furthermore, experienced companies often have a greater understanding of the manufacturing process and are better able to anticipate problems.

Quality control is another important factor for metal fabricators. Poor quality can lead to defective products, which can hurt both the manufacturer’s reputation and its bottom line. Metal fabricators must vigilantly check all aspects of their products for defects to avoid this problem. Delivery time is also important for metal fabricators.

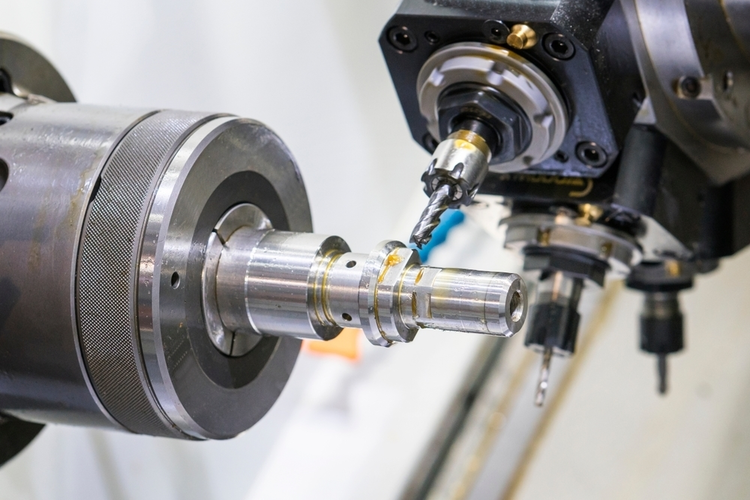

Metal fabrication machines are used to create different parts and products for different applications. By understanding What Are Metal Fabrication Techniques, you may want to know what machines are used for metal fabrication. There are a few different types of machines that are used for metal fabrication. These include lathes, grinding machines, drilling machines, broaching machines, and shaper machines.

© 2024 American Sheet Metal - All Rights Reserved