The Industrial Metal Fabrication Process

The industrial metal fabrication process is a popular method for creating products from metal. The process begins by cutting the metal into desired shapes using a variety of tools and machines. After the metal has been cut, it is then heated to a specific temperature to remove any impurities. Next, the metal is shaped into its final form and then polished or finished to perfection.

Industrial metal fabrication is an important process in the manufacturing of metals. It involves the production of metal parts and products by using advanced techniques and processes. The three main types of Industrial Metal Fabrication are machining, casting, and stamping. Each has its own set of advantages and disadvantages, depending on the parameters involved.

Industrial Metal Fabrication Techniques

Industrial metal fabrication techniques are constantly evolving to meet the ever-changing needs of the manufacturing industry. Today’s fabricators rely on a variety of metalworking processes to create complex components and structures from thin sheets of metal. This article will discuss some of the most common industrial metal fabrication techniques.

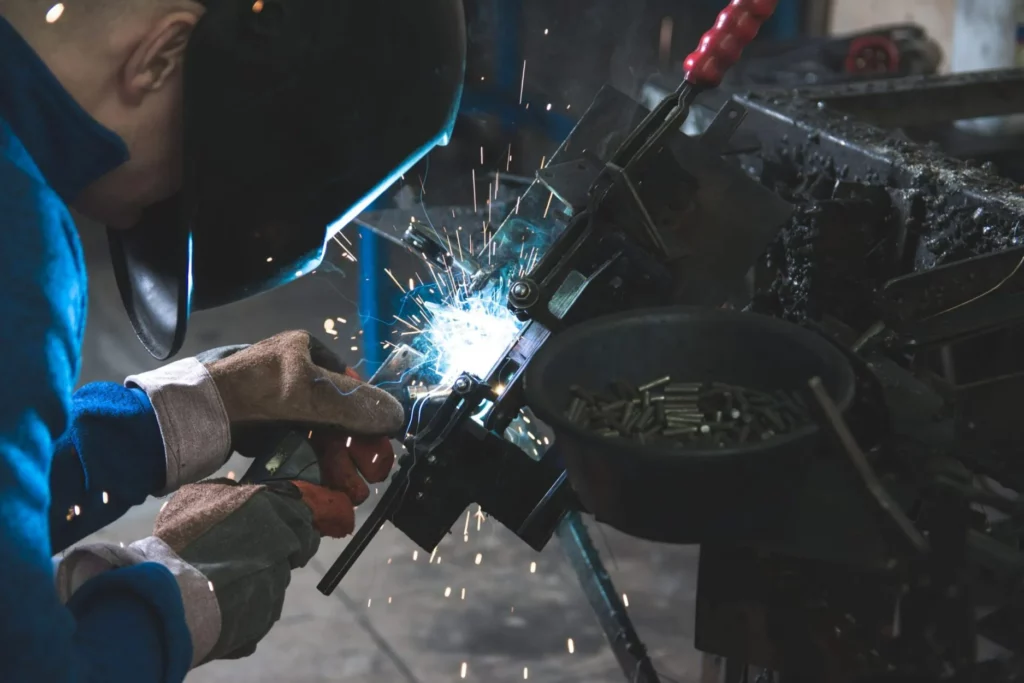

Joining: Welding is often used to join two pieces of metal together. The process involves heating the pieces until they become hot enough to melt, then adding filler material and welding the two pieces together. This method is often used for small, simple parts that don’t require a lot of strength or durability.

Extrusions: Extrusion is a popular method for creating complex shapes from thin sheets of metal. The process starts by cutting the sheet into the desired shape, then feeding it through a die that forms the shape into an elongated tube.

Industrial Metal Fabrication for Heavy Machinery and Equipment

Metal fabrication offers many advantages over traditional fabrication methods when it comes to heavy machinery and equipment. Not only is a metal more durable and efficient than other materials, but it can also be customized to specific needs. In addition, metal fabrication is versatile enough to handle a wide range of tasks and applications.

One example of where metal fabrication can shine is in the manufacturing of heavy machinery and equipment. Metal alloys are often stronger and more durable than their counterparts made from other materials, making them ideal for use in this type of equipment. Additionally, customizations like weight distribution and heat dissipation can be easily implemented using metal fabrication techniques. This makes machines that are both powerful and efficient.

What Are The Different Methods In Metal Fabrication?

There are several different methods used in industrial metal fabrication. The most common are forging, machining, and casting. Each has its own set of benefits and drawbacks.

Forging is the oldest method of metal fabrication. It involves heating a piece of metal until it can be shaped by hammering and then cooling it into its final form. This process is labor-intensive and requires skilled workers.

Machining is the most popular method of metal fabrication because it is fast and easy to use. Machining involves using a series of rotary tools to cut or shape metal pieces. This process is versatile and can be used to create complex shapes or small parts.

Casting is a process used to create complex objects from simple shapes by pouring molten metal into a mold that has been designed specifically for the object being created.

What to Consider When Choosing a Company?

Choosing the right company like American Sheet Metal for your industrial metal fabrication project can be a daunting task. There are several factors to consider, including experience, equipment, and pricing. Here are some tips to help you get started:

- Look for a company with experience in your specific type of fabrication. Not all companies are equipped to handle all types of projects, so it’s important to choose one that is qualified to do the job right.

- Equip yourself with accurate specs and rough estimates before starting any negotiations. A well-educated client will be able to give you accurate quotes based on their needs, not what they think you might want to hear.

- Be realistic about price expectations and understand that not all companies offer competitive rates. It’s important to compare apples to apples when shopping around for a company.

What Type Of Industry Is Metal Fabrication?

Metal fabrication is a process of creating objects or parts from metal by shaping them using tools, welding, heat, and pressure. The most common metals used in metal fabrication are aluminum, brass, copper, stainless steel, and titanium.

Industrial fabrication is the process of manufacturing large items such as bridges, skyscrapers, and airplanes. Metal fabrication is used in this process to create the various parts needed for these large projects.

The most common types of metal fabrication are machining, stamping, forging, and casting. Machining is the process of using machines to cut or remove material. Stamping is the use of a press to create patterns on metal. Forging is the process of heating metal until it becomes malleable and then forming it into a desired shape using a hammer or anvil.

Which Material Is Used For Fabrication?

Industrial metal fabrication is a process in which materials are forged, cut, and formed into various objects. Many materials can be used for fabrication. Here are some of the most popular ones:

Aluminum: This metal is popular because it is lightweight and easy to work with. It’s also strong enough to support heavy loads, making it a good choice for industrial applications.

Iron: Iron is a commonly used material because it’s strong and durable. It can be welded together to create complex structures, which makes it a popular choice for industrial fabrications.

Steel: Steel is another common material for industrial fabrications because it’s both strong and affordable. It can be shaped into any desired shape, making it a versatile option for many applications.