Importance of Industrial Metal Fabrication

Have you ever wondered why industrial metal fabrication is so important? This process is essential for a variety of reasons, and it’s important to understand the importance of metal fabrication to fully appreciate its value.

Industrial metal fabrication involves the shaping and forming of metals into useful parts, components, and products. These metals can be used in the manufacture of machinery and vehicles, furniture, structures, tools, and many other applications. The process requires a range of skills and techniques to ensure that the end product is a safe and effective one.

In this article, we’ll discuss the importance of industrial metal fabrication and why it’s an essential part of many industries. We’ll look at the various processes involved in fabricating metal products as well as how they benefit businesses in both the short term and long term. Finally, we’ll give an overview of what to consider when choosing a metal fabricator for your purposes.

Safety Concerns with Industrial Metal Fabrication:

Industrial metal fabrication plays an essential role in the safety of many industries, from aerospace and automotive to defence and medical. This is because metal fabrication can be used to create a variety of parts, components, and structures that meet exact requirements for design, strength, and precision.

Moreover, the Importance of Industrial Metal Fabrication is that it allows for the creation of parts that can withstand extreme temperatures, pressures, or corrosive environments better than some other materials. This is critical for applications such as those found in the nuclear energy industry or critical medical equipment, where there should be no compromise when it comes to safety.

Lastly, metal fabrication also ensures that all parts are produced uniformly according to exact specifications. This means that all parts are made with consistent materials, meeting all safety standards every single time. This uniformity in production can ultimately help reduce maintenance costs associated with individual part manufacture while also providing greater assurances of safety and reliability.

Types of Industrial Metal Fabrication:

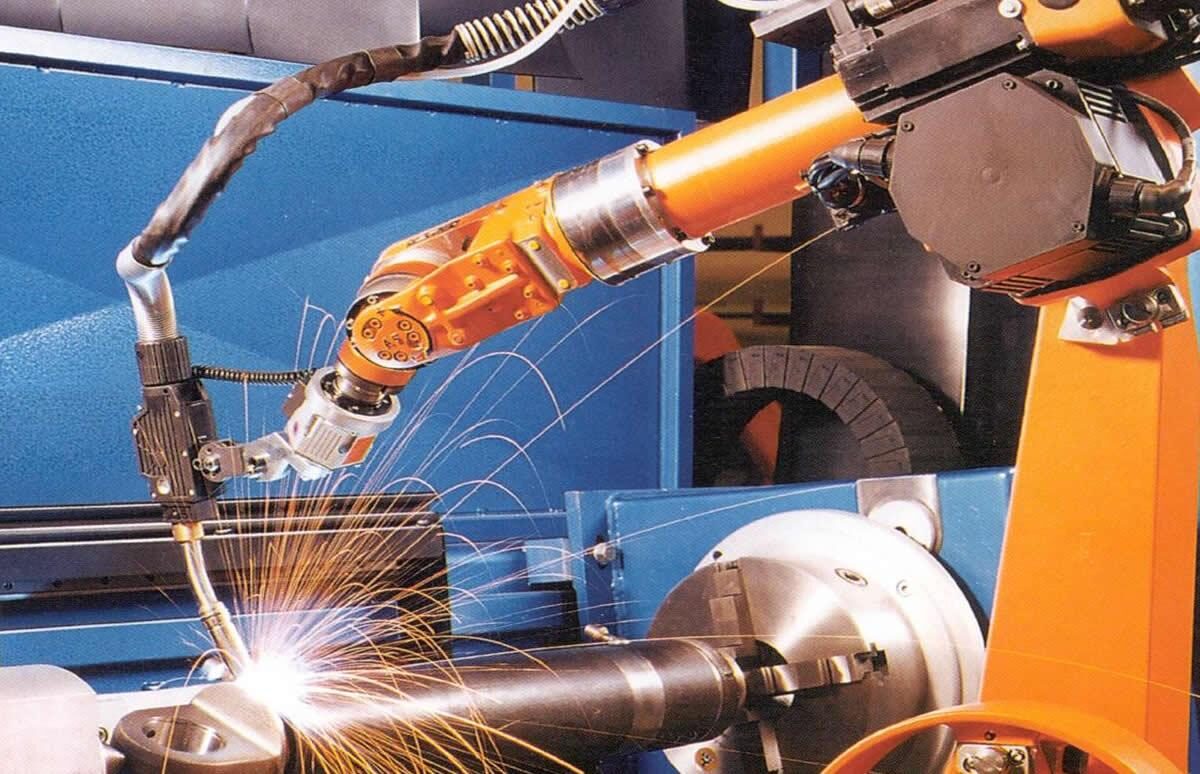

Industrial metal fabrication is an essential process for creating a wide range of products used in many industries. It involves the transformation of raw materials into components or finished goods using processes like welding, cutting, and forming. The types of Industrial Metal Fabrication vary depending on the project. It could include:

Welding: This is one of the most widely-used processes and involves combining two pieces by applying heat, pressure, or both.

Cutting: This process involves cutting metal shapes into specific patterns by using tools such as scissors, shears, saws, drills, or lasers.

Forming: This type of fabrication is used to create complex parts from sheet metals and requires specialized tools such as presses and punches.

Machining: This process uses computer numerically controlled machines to create highly accurate parts from a range of materials with great precision.

It is important to ensure that the right type of industrial metal fabrication is used for each project to achieve the desired results. With the help of experienced fabricators, businesses can ensure that their projects meet their specifications and are completed on time and within budget.

Benefits of Industrial Metal Fabrication:

Industrial metal fabrication is an important process, as it enables businesses to create structures and items constructed from metal. This process has been used for centuries and many products might not exist without it. Here are a few of the benefits and Importance of Industrial Metal Fabrication:

Cost Efficient:

Metal fabrication can be cost-effective, as metal is often less expensive than other materials. Additionally, workers can use metal fabrication techniques to create complex structures quickly, reducing labour costs.

Durability:

Metal is a strong material, which makes it perfect for creating durable objects that are resistant to wear and tear. In addition, metal has excellent corrosion resistance and can withstand extreme temperatures, making it ideal for products meant for outdoor exposure or those exposed to extreme conditions.

Versatile:

Metal fabrication allows businesses to create a wide range of objects using steel and other metals such as aluminium or copper. This versatility makes it possible to tailor pieces according to individual needs and specifications. Furthermore, this versatility also allows companies to quickly create prototypes without having to invest in additional tools or equipment.

By utilizing the benefits of industrial metal fabrication, businesses can gain from its cost efficiency, durability, and versatility all critical components of success in today’s competitive market environment.

Cost-Effectiveness of Industrial Metal Fabrication:

The cost-effectiveness of industrial metal fabrication is one of the primary reasons why it is such a popular option for any project requiring precision and strength. This is because the process of creating a single, high-quality piece of metal is much less expensive than creating multiple pieces through traditional manufacturing processes.

By using industrial metal fabrication, you can save materials, labour costs, and time. In addition, the technology used in this process allows for mass production, which helps you save on production costs. Furthermore, with less wasted material and fewer defects in the final product, you can also reduce your overall costs.

Industrial metal fabrication also offers greater control over the quality of your finished product. By utilizing advanced technologies such as laser cutting or computer-aided design software tools, you can create custom parts that are unique to your product’s needs. In addition, with automated processes such as welding and assembly, you can ensure that each part works together as it should and that the finished product is made from high-quality materials.

Role of Advanced Technology in Industrial Metal Fabrication:

Industrial metal fabrication plays a vital role in a wide range of industries, and the need for it is increasing. Using traditional methods, like manual welding and cutting, was inefficient and labour-intensive. Thankfully, engineering advancements have revolutionized industrial metal fabrication.

Modern technologies such as computer-aided design and computer-aided manufacturing allow for more precise designs that can be replicated with the help of automated systems. These automated machines are capable of accomplishing tasks at a rate an order of magnitude faster than manual approaches with fewer mistakes and higher accuracy.

The use of advanced software programs also enables manufacturers to remotely monitor their processes and maintain quality control. This means products can be produced faster with greater accuracy at lower production costs than ever before. In addition, advanced technologies are also used to make custom parts for various applications, giving businesses the ability to create unique products tailored to their client’s needs.

Moreover, automation cuts down on labour costs by reducing the number of staff needed for production and removes individual biases from the production process, guaranteeing that each part is made with exact precision every time. The result is that manufacturers can produce parts more efficiently while using fewer resources allowing them to remain competitive in an ever-changing market.