Industrial Metal Fabrication and Sustainability: How to Reduce Waste and Energy Consumption

Industrial metal fabrication can have a big impact on the environment. It takes a lot of energy to fabricate metals, and it results in large amounts of waste that can be difficult to dispose of. But, with the right strategies, it is possible to reduce waste and energy consumption while still producing quality products.

In this article, we will explore how industrial metal fabrication can help to reduce its environmental impact. We will look at ways to make processes more efficient and reduce energy use, as well as how to properly dispose of waste products and recycle materials. Finally, we will discuss how these measures can lead to a more sustainable future for industrial metal fabrication.

Benefits of Sustainability Practices in Industrial Metal Fabrication

When it comes to industrial metal fabrication and sustainability, there are numerous benefits to making the switch. Not only does it help to reduce waste and energy consumption, but it also improves worker safety, reduces costs, and promotes community goodwill. Let’s take a closer look at how sustainability practices benefit Industrial Metal Fabrication:

- Reduce Waste: Sustainable practices help to minimize raw material and energy waste by utilizing lean manufacturing techniques such as the reuse and recycling of materials. This can have a significant positive impact on both bottom-line cost reduction and environmental impact.

- Reduce Energy Consumption: By utilizing pieces of equipment that are designed for efficiency such as high-efficiency pumps, valves, fans, and motors energy consumption can be greatly reduced in industrial processes. Additionally, implementing better insulation for heat loss prevention or capturing off-gasses can make all the difference when it comes to energy conservation.

- Improve Worker Safety: Sustainability initiatives can help improve workplace safety by reducing exposure to toxic materials in the facility through the use of green cleaning products and recycling initiatives. Additionally, switching to more efficient equipment can help reduce workplace risks associated with manual labor-intensive processes.

All in all, sustainable processes in industrial metal fabrication are an important step toward creating a greener planet while also realizing cost savings that perform double duty.

Enhancing Production Processes for Sustainability:

Industrial metal fabrication processes require a lot of energy and resources. Although the production process usually results in efficient, long-lasting products, it may also lead to unnecessary wastage. By finding ways to reduce waste and energy consumption, your business can operate more sustainably.

Measuring the Output:

To start, you should measure current output in terms of materials used and energy consumed for production. This can help you identify areas where improvements could be made.

Increasing Efficiency:

By streamlining processes and reducing the number of steps or tools needed for production, your company can become more efficient in its use of resources. Automation techniques also reduce wastage as they allow for precise control over the production process. Additionally, using eco-friendly machines with low-energy consumption will help reduce overall energy use in your facility.

Reusing and Recycling Materials:

You can also work on reusing materials wherever possible. Reusing materials is not only sustainable but cost-effective too, as it reduces the need to buy new raw materials, with all its associated costs. Likewise, recycling metal scraps and waste products will help reduce landfill waste while at the same time providing an environmentally friendly solution that helps conserve natural resources.

Techniques to Reduce Waste:

You can reduce waste in your industrial metal fabrication projects in several ways. Here are a few that you can start implementing today:

Utilize scrap material: Find ways to reuse scrap material, such as creating new parts or components from the leftover materials. You can also recycle scrap material to reduce the amount of new raw materials needed for production.

Embrace additive manufacturing: Utilize 3D printing and other types of additive manufacturing technologies in your fabrication processes to reduce the amount of wasted material. This method also offers greater design flexibility and faster prototyping, which can help you save time and money.

Invest in automation technology: Automation has come a long way in recent years and it can help you reduce energy consumption while increasing production throughput. Automation can also reduce labour costs and improve product quality by eliminating human error during production.

Strategies to Improve Energy Efficiency:

The industrial metal fabrication industry has made great strides in becoming more sustainable, but there is always room for improvement. Here are some strategies to reduce energy consumption during the manufacturing process:

Automation:

Automation technologies can help to reduce waste and improve accuracy in metal fabrication operations. Automation also increases the efficiency of tasks and reduces the amount of time needed to complete them. This can save energy by reducing the need for manual labour, as well as increasing productivity.

Improved Tool Design:

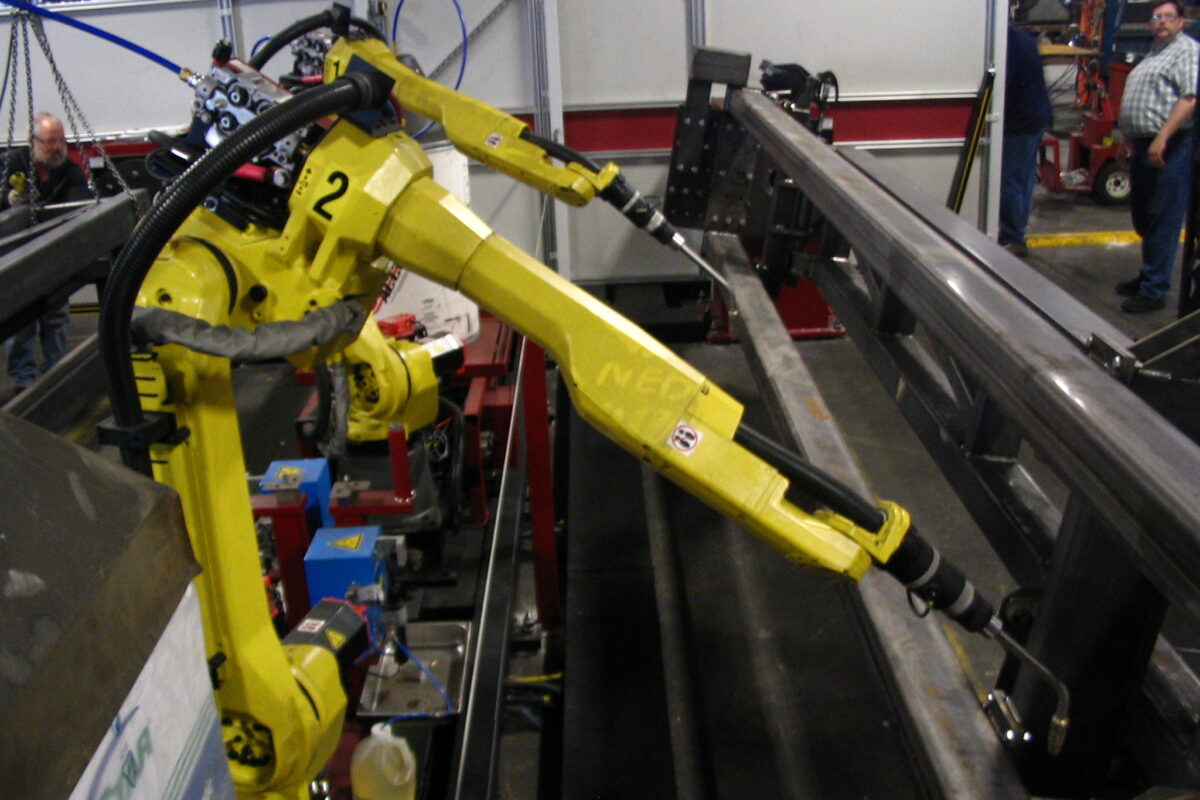

By employing improved tool design, the amount of energy used in metal fabrication processes can be reduced significantly. This includes changes such as making sure tools are properly cooled and lubricated, which improves both their accuracy and speed. The use of specialized tools such as robotic arms improves accuracy and can significantly reduce energy consumption.

Resource Efficiency:

The use of resources such as materials and water should be carefully managed to maximize efficiency and reduce waste. Recycling scrap materials is one way to achieve this goal, as it reduces the need for new resources while still producing high-quality products. Additionally, using renewable sources of energy, such as solar or wind power, can help to lower energy costs associated with metal fabrication processes.

Enhancing Production Processes for Sustainability:

Industrial metal fabrication processes require a lot of energy and resources. Although the production process usually results in efficient, long-lasting products, it may also lead to unnecessary wastage. By finding ways to reduce waste and energy consumption, your business can operate more sustainably.

Measuring the Output:

To start, you should measure current output in terms of materials used and energy consumed for production. This can help you identify areas where improvements could be made.

Increasing Efficiency:

By streamlining processes and reducing the number of steps or tools needed for production, your company can become more efficient in its use of resources. Automation techniques also reduce wastage as they allow for precise control over the production process. Additionally, using eco-friendly machines with low-energy consumption will help reduce overall energy use in your facility.

Reusing and Recycling Materials:

You can also work on reusing materials wherever possible. Reusing materials is not only sustainable but cost-effective too, as it reduces the need to buy new raw materials, with all its associated costs. Likewise, recycling metal scraps and waste products will help reduce landfill waste while at the same time providing an environmentally friendly solution that helps conserve natural resources.

Adopting Sustainable Policies in Metal Fabrication:

Industrial metal fabrication involves a complex series of processes that consume energy and resources. To ensure sustainability is achieved in these processes, many manufacturers have adopted certain policies and practices. Some specific actions that many industrial metal fabrication companies have taken to reduce their environmental impact include:

- Investing in energy-efficient equipment.

- Recycling metals, from scrap to finished products.

- Reducing electricity use.

- Implementing waste reduction programs.

- Implementing green initiatives such as reusing materials and minimizing water and air pollution.

These policies can help reduce manufacturers’ carbon footprints, as well as preserve natural resources that are essential for the manufacturing process. Additionally, these strategies can help keep costs down and improve efficiency, leading to a better bottom line for manufacturers and greater sustainability overall.