Share the Post: Facebook Linkedin Twitter Pinterest Bending and forming are crucial processes in sheet metal fabrication, allowing flat sheets to be transformed into complex shapes and structures. The techniques used can significantly affect the precision and quality of the final product. This article provides a detailed guide on different...

Share the Post: Facebook Linkedin Twitter Pinterest ASM Industries recently completed an exciting project at Disneyland's Tomorrowland, involving the installation of unique features to enhance the aesthetics and functionality of a prominent kiosk.The ChallengeThe goal was to upgrade the kiosk's design while addressing practical concerns such as water resistance and...

Share the Post: Facebook Linkedin Twitter Pinterest The longevity and functionality of buildings rely heavily on high-quality materials that strike a balance between durability and aesthetic appeal.Among these materials, chrome-plated metal cladding panels have always proved to be an excellent choice that satisfy these conditions in architectural design. Let's dive...

Share the Post: Facebook Linkedin Twitter Pinterest ASM Industries engineered the sleek and accessible LED Screens showcased at Sunset Spectacular. The project required engineers to install LED screens within a ½ inch stainless steel plate structure, as well as custom A.C.M (Aluminum Composite Material) trim/bezel around the LED screens.This ensures...

Share the Post: Facebook Linkedin Twitter Pinterest Along with technology, the construction industry is consistently evolving. Because of this, we see innovative solutions continue to emerge to meet the demands of modern infrastructure. Amidst the evolution, embedded steel plates continue to hold up various inventive structures. We see this in...

Share the Post: Facebook Linkedin Twitter Pinterest As we know, construction and design demand a rigorous selection of building materials. They undoubtedly play a critical role in shaping the visual and functional aspects of structures. This is where Aluminum Composite Material panels come in. In this article, we will explore...

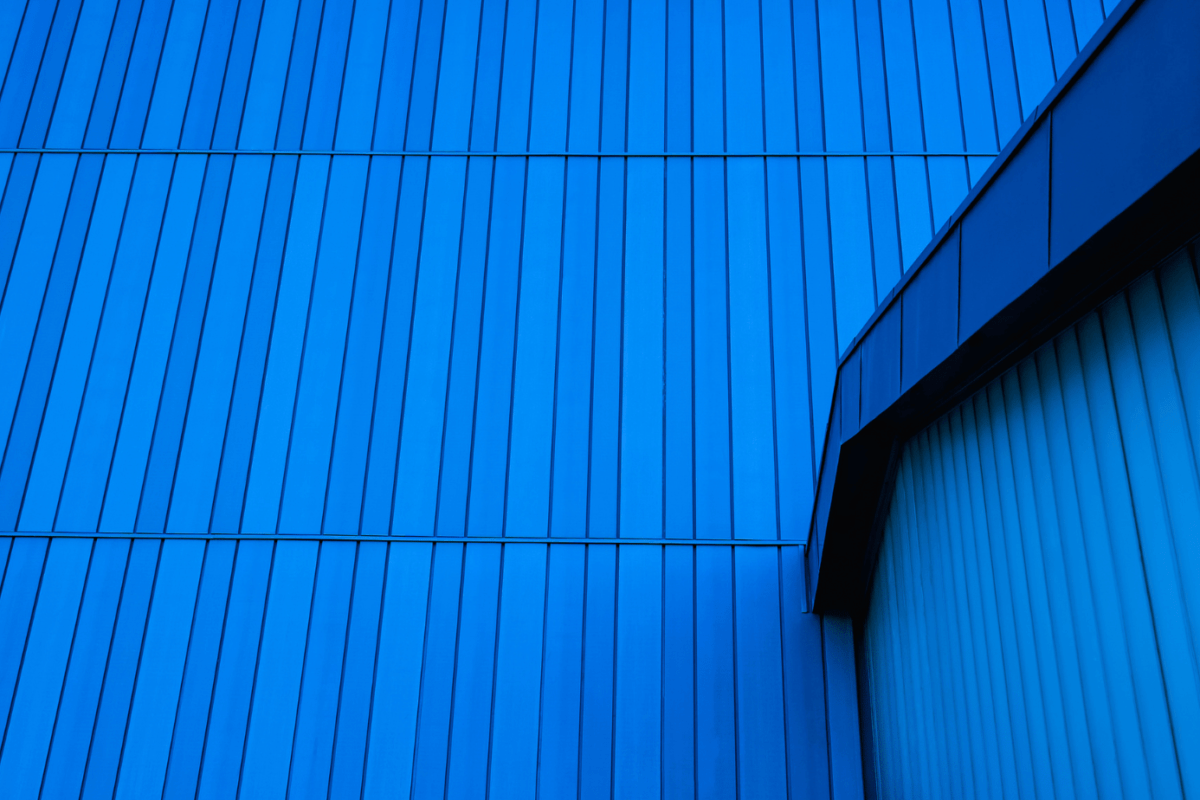

Share the Post: Facebook Linkedin Twitter Pinterest In the heart of the Foothill Gold Line project lies the MOW building. ASM was entrusted with the critical task of supplying roof and wall panels that would fortify this structure.The ChallengeBecause of the elements in the Foothill region, the project demanded an...

Share the Post: Facebook Linkedin Twitter Pinterest The USC Compounding Lab embarked on a project to establish new compounding stations. Recognizing the role of safety and compliance in pharmaceutical compounding, the lab sought a partner that could deliver top-notch solutions to fortify their operations.In pursuit of excellence, the USC Compounding...

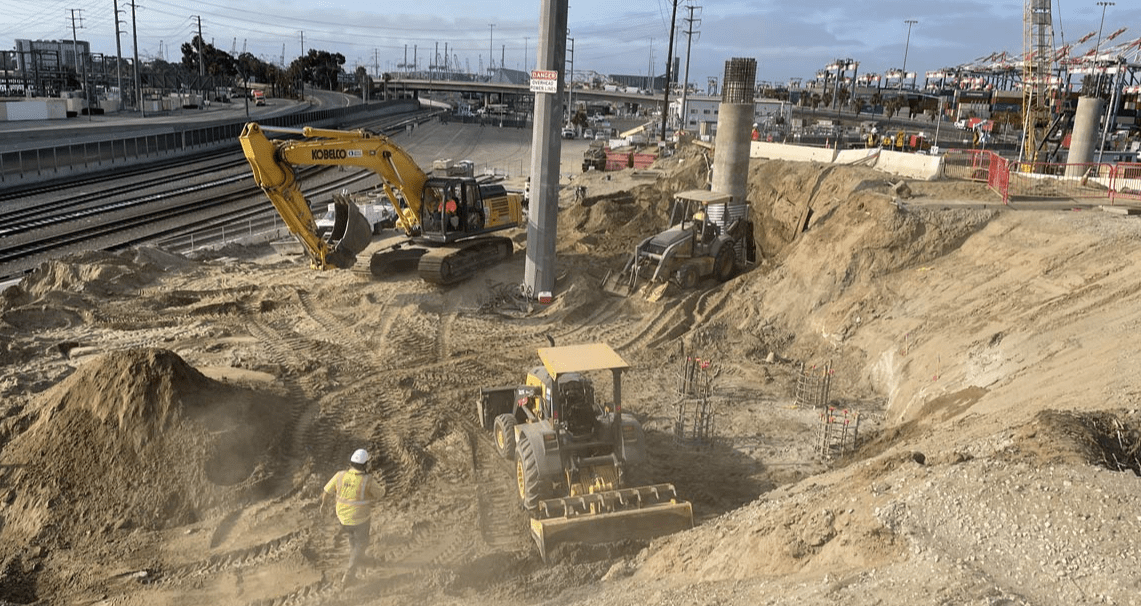

Share the Post: Facebook Linkedin Twitter Pinterest ASM Industries successfully completed a transformative project in Long Beach, CA, which improved the functionality and aesthetics of the area. The Ocean Boulevard Coastal Bike Trail Connector aimed to provide a safer and more accessible route for cyclists and pedestrians, involving the construction of...

Share the Post: Facebook Linkedin Twitter Pinterest ASM Industries embarked on an ambitious project to revitalize a business park in Rancho Cucamonga. The project involved the facade renovation of three buildings, aiming to not only modernize their appearance but also enhance their structural integrity using advanced architectural solutions.Location: Rancho Cucamonga,...